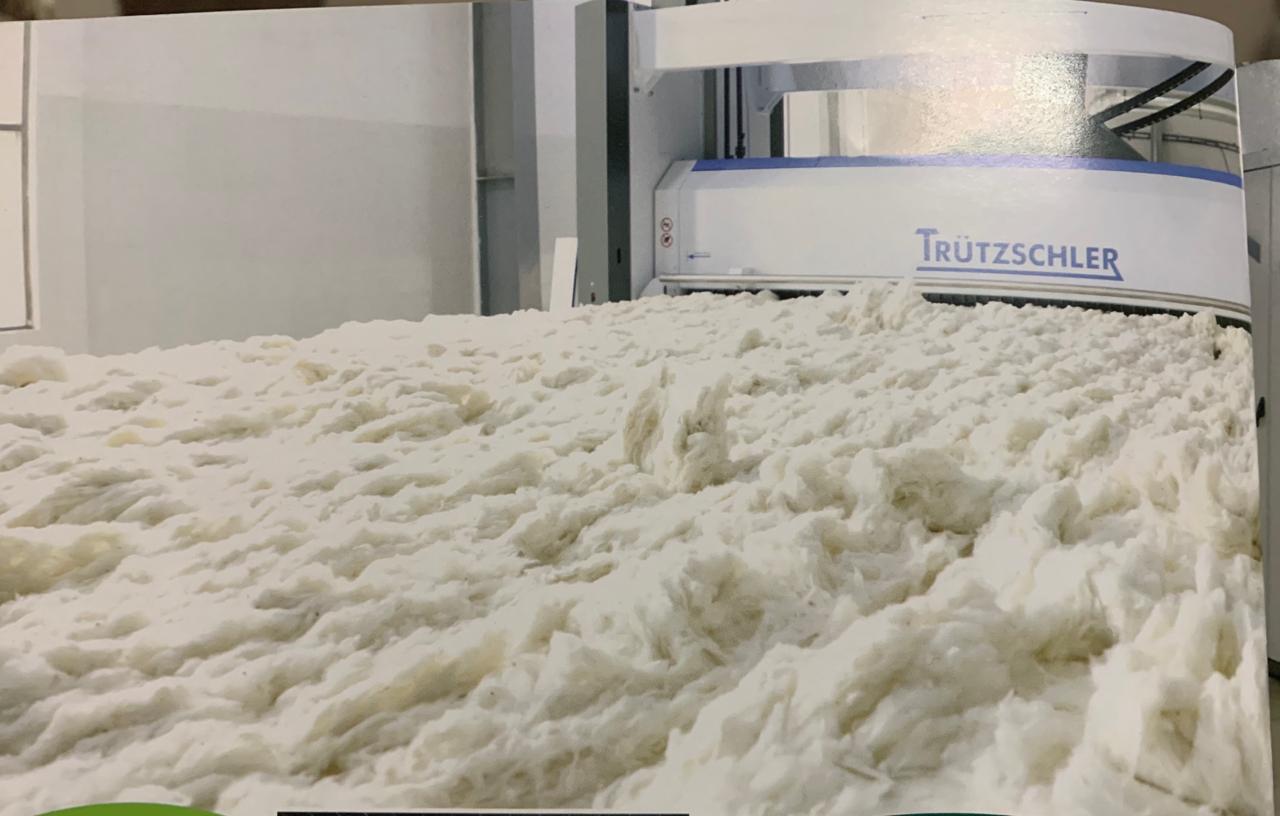

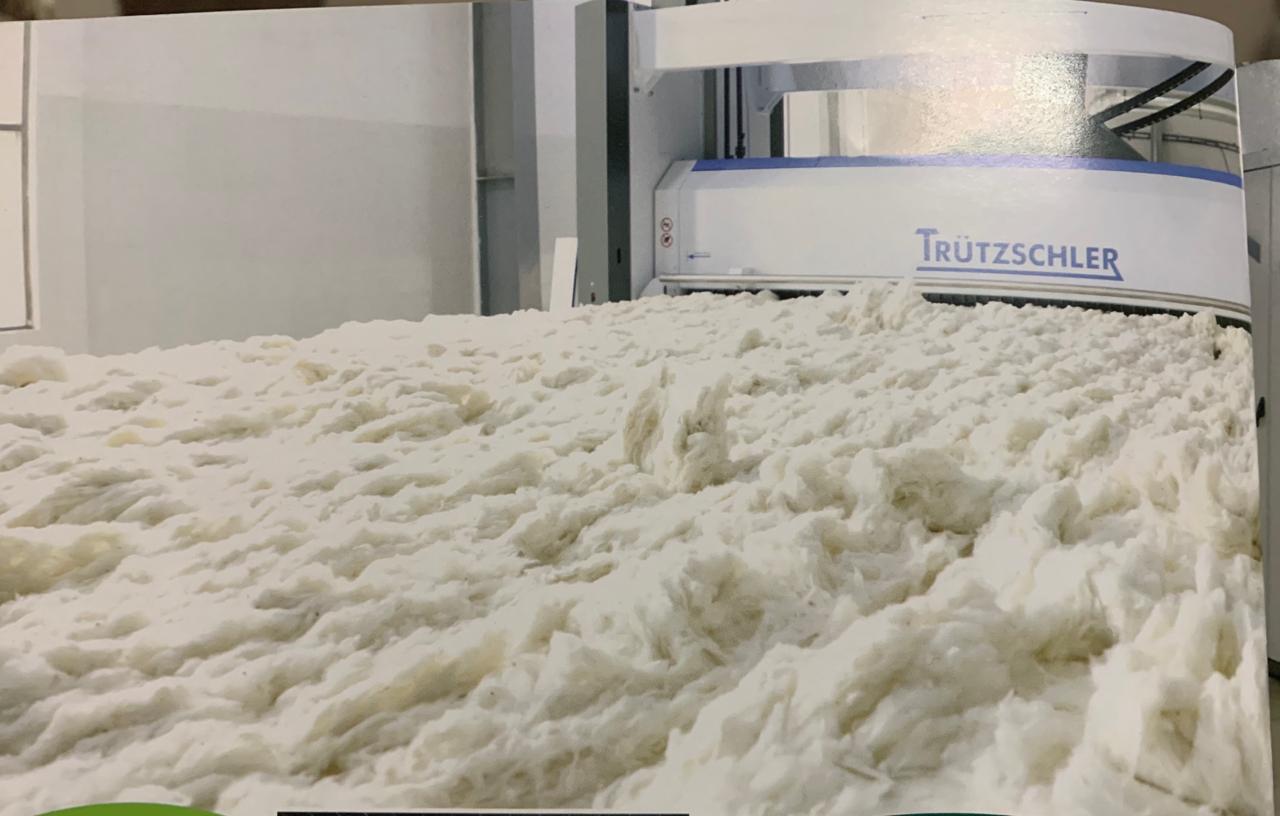

Blowroom

The use of advanced machinery from Trutzschler in Karim Tex Blowroom is a great investment in the production of high-quality yarn. With the advanced machinery, Karim Tex ensure that yarn is free from any impurities, resulting in a more consistent and higher-quality product.

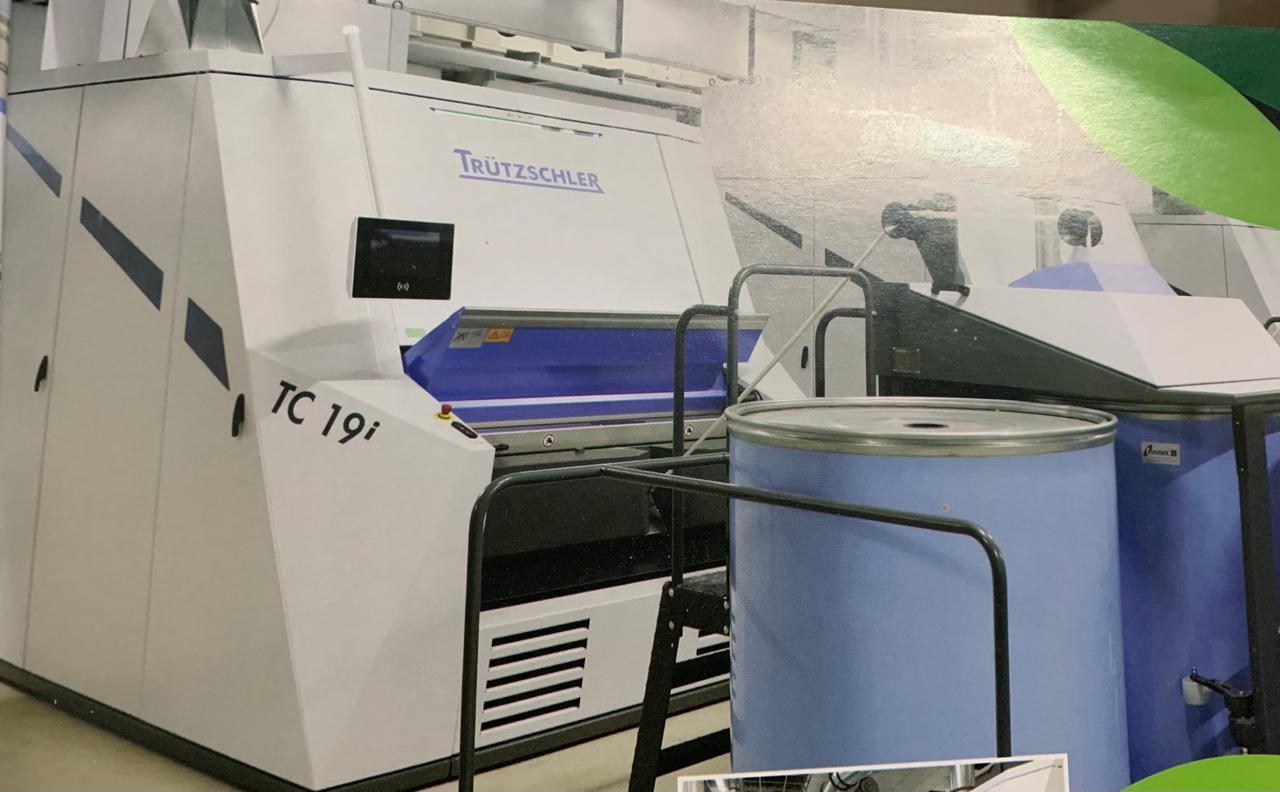

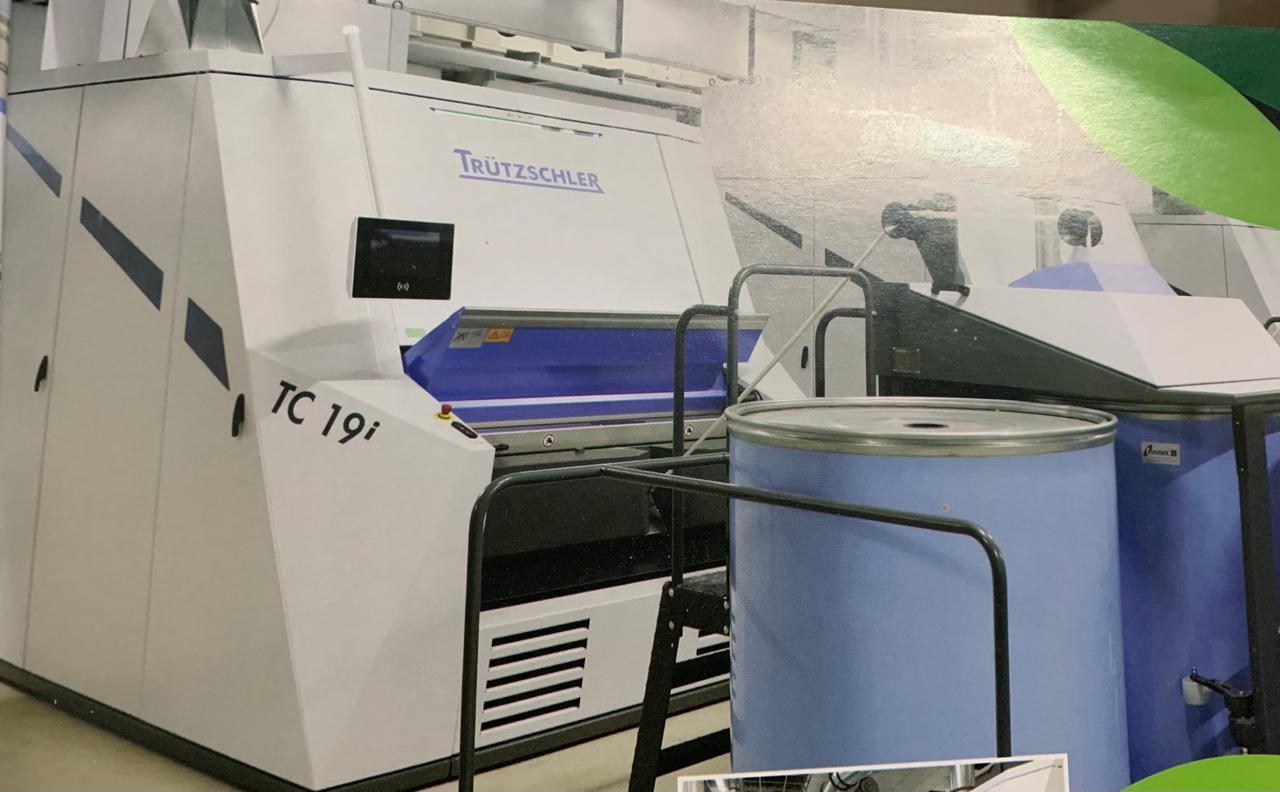

Carding

Carding is the heart of spinning. With the latest TC 19 carding machine from Trutzschler, Karim Tex can ensure that fibers are well prepared for the spinning process, which will ultimately result in high-quality yarn. The machine's advanced features allow for precise control over the carding process, which minimizes any variations in the output and ensures consistent quality.

Draw Frame

Double delivery Draw Frame from Rieter is a great addition to Karim Tex's production process, as it can help to achieve its daily production targets more efficiently. The machine is also designed to ensure consistent quality of the output, which is critical in the spinning process.

Comber

The comber section is a crucial part of the spinning process that plays a significant role in producing high-quality yarn. 15 sets Comber from Rieter helps to improve the yarn's evenness, reduce short fibers, and enhance its overall quality. By investing in top-of-the-line comber machines, Karim Tex is committed to delivering yarn products of exceptional quality to meet the demands of customers.

Simplex

The Simplex with auto doffing system and bobbin transport system is revolutionizing Karim Tex's yarn production process. The auto doffing system can help to reduce downtime during the doffing process, which is critical in maintaining a high level of production efficiency.

Ring Frame

By combining the Ring Frame from LMW with the Link Coner from Muratec, Karim Tex can create a highly efficient and automated production line that can handle a wide range of fibers and produce high-quality yarn with minimal downtime and waste. This can help to increase production capacity and improve the overall efficiency and profitability of the operation.

Bobbin Transport System

The bobbin transport system is designed to transport the bobbins automatically from the Simplex to the next process in the production line, which can help to reduce labor costs and improve the overall efficiency of the operation.

Auto Waste Bale Machine

Karim Tex has implemented an automated system to collect and bale the waste generated from the blowroom and carding sections. By collecting the waste automatically, Karim Tex can reduce the amount of labor required to manage the waste, and also minimize the risk of contamination and damage to the final product. The auto bale machine can compress the waste into tightly packed bales, making it easier to transport and dispose of.

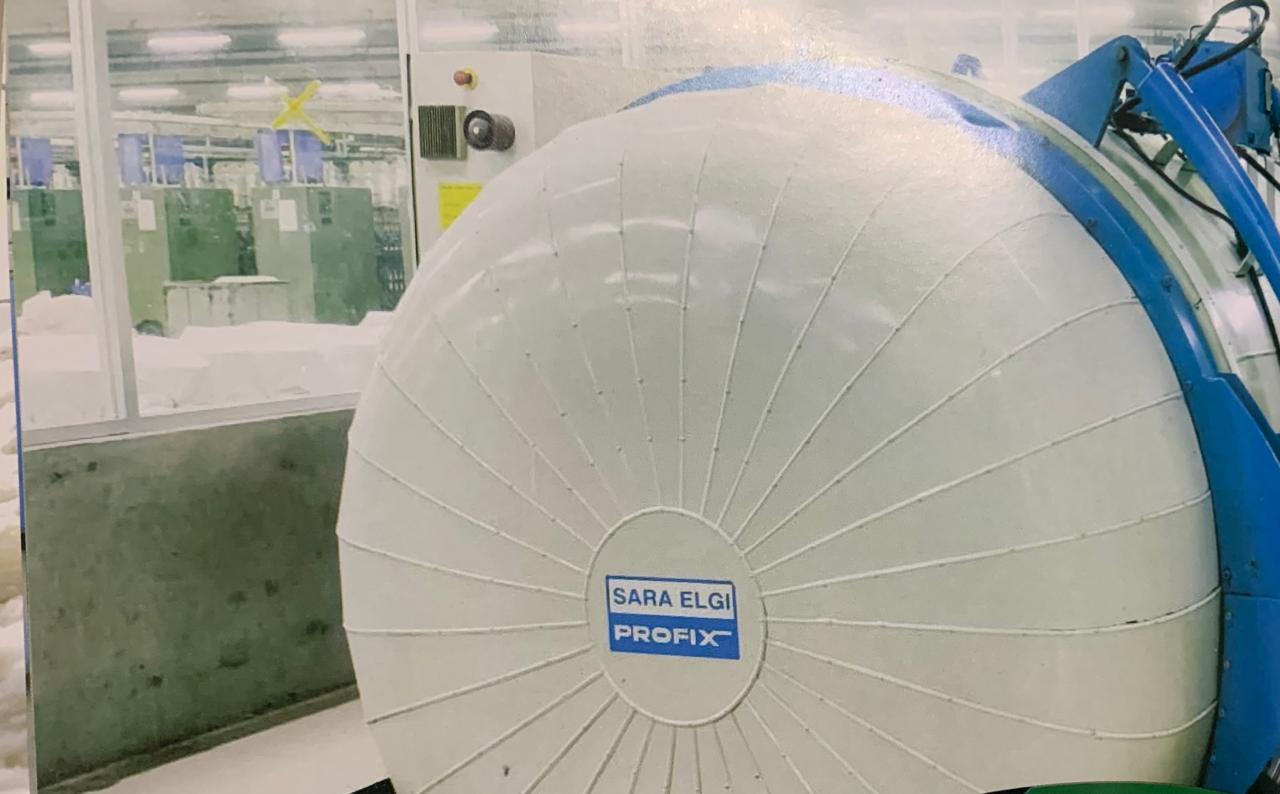

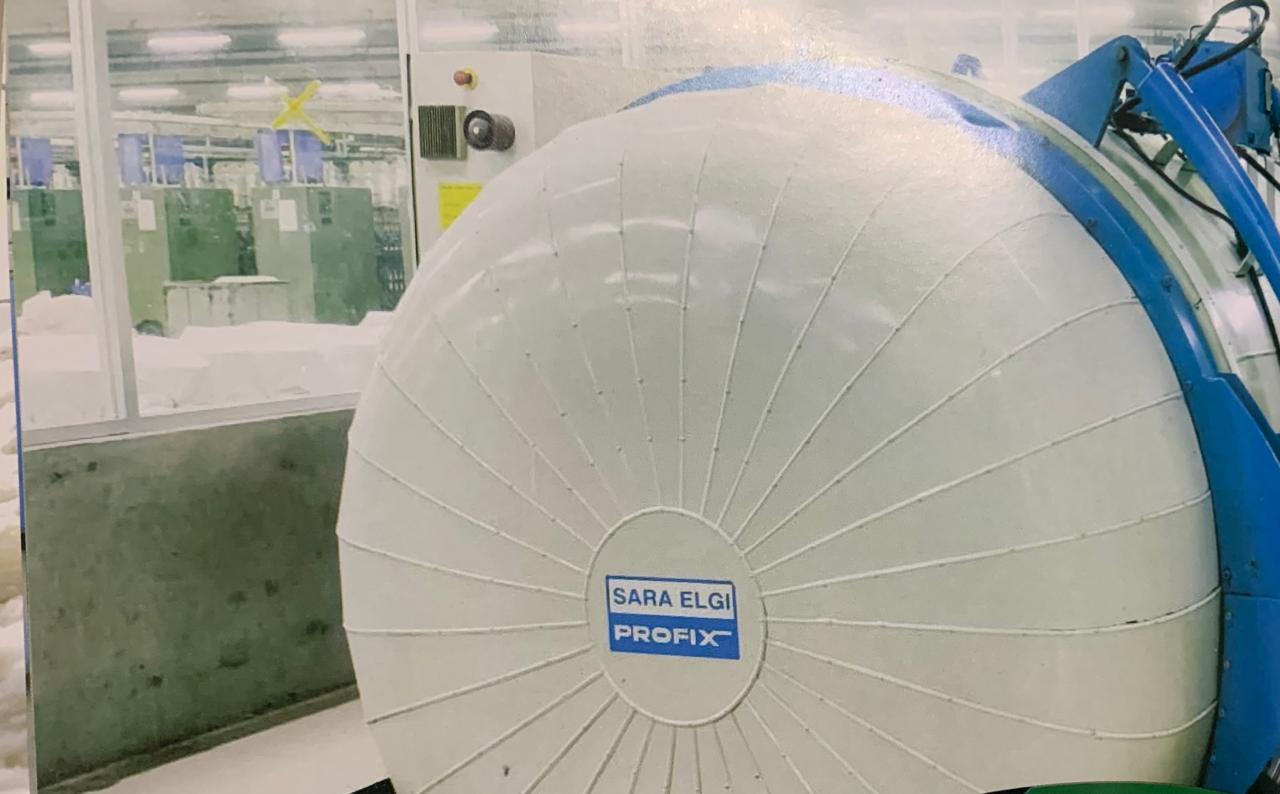

Yarn Conditioning M/C

Yarn conditioning is designed to set the yarn twist and make it smoother, which ultimately ensures the best possible performance of the yarn during fabric production. This attention to detail is just one of the many ways that Karim Tex delivers superior products and customer satisfaction.